Avro Lancaster NX611 ‘Just Jane’: This week we have dismantled the number 4 propeller and rebuilt the number 3 propeller.

The old number 3 prop will replace number 4 prop as it has its 5 year AD check which will be done at a Prop overhaul shop.

We had a great meeting with BBMF Project Team regarding their structural work in the coming months and years and updating them on our work, just another part of our close working relationship.

One of the team made the long old trip back up to Cumbria to collect the wing tip extrusion which had been going through heat treatment by Capalex to T511 standard.

Now that the extrusions are back with us the set for BBMF will be collected by ARCo from Duxford and we can copy drill them from the originals to build up the web and the basis of the wingtip rebuild.

Once the extrusions are drilled the chords and web will be offered up to the wing to make sure it fits before the whole wingtip is built.

Our team driver has also been back down to Mark Cole and Simone Cunningham on the south coast to collect parts for the starboard wingtip and drop off a skin for the rear fuselage which is a very complex curve and needs Simones skills to wheel it.

The other skin for the rear section took 5 hours to wheel! Some of the parts which have come back from Simone are the shaped stringers (you can see one of these in a photo in the image list below).

When you see the amount of curve in the stringer it really shows how much the wingtips curve to the wingtip.

Seeing the wingtips when fitted to the aircraft you really don’t realise the amount of shape in this relatively simple structure.

The port wing tip is continuing through the rebuild stage as its built up with original parts and then new parts are swapped in and drilled off. Its all a very time consuming job but ensures that the structure does not change shape.

We’ve had another batch of parts go through the paint shop with Martin and Keith including many of the skins for the starboard wingtip and the stringers which require the reinforcing strip to be riveted in before it goes into the main structure.

Next week should see many of the brackets in the port wingtip structure drilled off and a lot of the structure ready for paint.

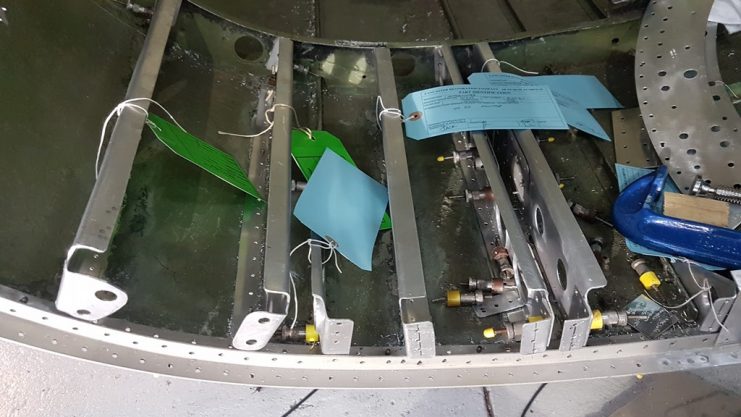

Jack has been progressing the rear fuselage with all of the new intercostals trial fitted and drilled off, the new former has been trial fitted and drilled off and the bulkhead has been offered up ready to be drilled off next week.

Very shortly the rear fuselage parts will be ready to be removed and painted ready to be finally fitted to the rear fuselage. Once the rear structure is riveted in place Jack can move on to reconstructing the bottom of the turret section and refitting the ‘hoop’ that the turret sit in.

We’re still waiting on the new turret ring which is spun steel but it hopefully won’t be too long before it has been produced and can be trial fitted to the ‘hoop’ and copy drilled from the original.

It was mentioned in the previous Rivet Club email that we are in need of a bulk more Cleco pins. The response to this has been remarkable with 5 donors contributing to the costs and one supporter covering the cost of the pins entirely.

We are extremely grateful to all those who have helped with this extra cost.

The money donated over and above what was required for the Cleco pins have enabled us to purchase a ‘Linisher’ which is a piece of equipment which will make the trimming and filing of skins and structure much quicker therefore saving the project time and money in the future.

We have just received notification from Aircraft Extrusions in the USA that our order is complete.

This goes back to the order for the fuselage stringers (the whole reason we had to change the plan for this winter to rebuild the wingtips instead of the rear fuselage section) and the fin spars.

So very shortly we are going to have a £7,500 invoice to pay, an added expense this winter that was not factored into the original budgeting.

If anyone would like to support the stringer and fin post costs with a further donation then we would be extremely grateful of the support and if you were to make a donation HERE then it would be great to see you adding in the comments section that it is for the stringers/posts just so we can keep a track of it.

It’s good to know we will be one step ahead of the curve for next winter when we tackle the rear fuselage.

Don’t forget to checkout our new RAF Blue/Grey Rivet Club t-shirts on the links below. We have changed the colour from the khaki green to try and offer some variation. I could see no better colour than RAF Blue/Grey!

An absolutely fantastic and historic restoration and you can help this Lancaster back into the skies where she belongs. Please check out and follow and support www.lincsaviation.co.uk and sign up to their newsletter

If you’re enjoying these newsletters but there is something in particular you would like me to cover or something more you would like me to focus on then please do get in touch to enquiries@lincsaviation.co.uk

Thanks for your support!

Andrew Panton

More Photos!

Iconic Last-of-its-Kind LCT 7074 About to Go On Display