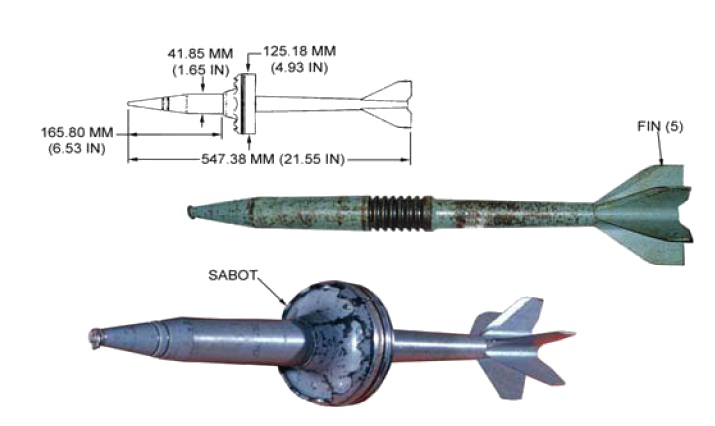

Inner workings of the Sabot round

A sabot round works by pairing a slender, high-speed penetrator with a broader, lightweight sleeve that captures more of the propellant’s force. This sleeve—the sabot—keeps the sub‑caliber dart properly aligned as it travels down the barrel, enabling far greater acceleration than the narrow projectile could achieve alone. Moments after leaving the muzzle, the sabot peels away, allowing the penetrator to continue toward the target at velocities reaching several thousand miles per hour.

The penetrator itself is made from extremely dense materials such as depleted uranium and is designed to defeat thick armor through pure kinetic impact. Upon penetration, it breaks apart inside the vehicle, scattering high-energy fragments that devastate internal systems and crew, resulting in overwhelming and often decisive damage.

Different types of sabot rounds

There are five different types of sabot rounds. The cup sabot supports the base of the projectile and offers structural support around the shaft. It’s typically used in small arms ammunition, as well as smoothbore shotgun and muzzleloader projectiles.

The expanding cup sabot is similar to the cup round, in that it’s used for rifled small arms. However, when fired, the centrifugal force from the rotation of the projectile causes the segments surrounding it to open up. This introduces more surface area to the surrounding air pressure, releasing it.

The base sabot has a one-piece base that supports the bottom of the projectile, as well as separate pieces that surround the sides and center, breaking away once the round has been fired. This sabot is considered superior to the previous two, as it offers a cleaner and better sabot-projectile separation. However, it’s more expensive to produce.

The spindle sabot is typically used in large caliber armor-piercing ammunition. It uses between two and four longitudinal rings with a center section that makes contact with the projectile. The front centers the projectile in the barrel and provides an air scoop to help with its separation from the sabot, while the rear seals the propellant gases with an obturator ring along the outside diameter.

Finally, the ring sabot uses the projectile’s rear fins to center it, forming a single ring around the front with an obturator ring to seal the gases. This type of sabot was favored by the Soviet Union, as the steel from which it was constructed could withstand launch accelerations without needing a ramp to support the projectiles.

Multiple generations of sabot round munitions

The M829A1, also called the “Silver Bullet,” is a type of armor-piercing round used by tanks. It is designed to penetrate thick armor and has a long, depleted uranium projectile that is about 1.25 inches wide. When it strikes an enemy tank, it can punch through the armor and often causes a massive explosion, a phenomenon tank crews refer to as the “jack in the box” effect.

According to Sofrep, the M829A1 “is widely regarded as the most effective tank-fired (M1 Abrams 120mm main gun) anti-armor weapons in the world. It overwhelmed Iraqi armor during Operation Desert Storm. The M829A1 is a depleted-uranium long-rod kinetic energy penetrator round capable of defeating heavily armored vehicles.”

Over time, newer versions of the M829 round have been developed. The M829A2 improved the strength of the depleted uranium projectile, while the M829A3 enhanced the propellant to increase firing speed. The latest version, the M829A4, features a depleted uranium projectile and a specialized three-petal composite sabot for improved performance.

Use during Operation Desert Storm

More from us: 5.56 vs 7.62: Which is the Better Long Distance Round?

The M1A2 Abrams tank was used throughout Operation Desert Storm and fired 120 mm M829 sabot rounds at enemy armored vehicles; the projectiles took out multiple tanks as they dominated the battlefield. M829 sabot rounds are best used in armored warfare, rather than toward buildings or walls, so were thoroughly employed by the US military throughout the Gulf War.